Intelligent research and development

If an enterprise wants to transform intelligent manufacturing, it must first start from the root of product innovation, transform the serial R&D process into a closed-loop intelligent R&D process that is continuously improved according to the user’s needs, perceive the user’s needs and make flexible adjustments, and at the same time integrate the emerging enabling technologies related to intelligent manufacturing to form a product R&D cycle from user to user. That is to say, the analysis of market and user-related data begins at the stage of product design demand analysis, which includes the direct participation of users in the process of product customization based on their own preferences, and the feedback of relevant operating data during the use of products to guide the process of improving the original design scheme, forming an intelligent R&D process of continuous optimization.

「 1. Eight elements of intelligent research and development 」

The intelligent R&D process reflects the change in design history from designing for users, to helping users design, to users designing for themselves. Therefore, intelligent R&D must be based on the highly intelligent integration of design information, production information, user’s use and feedback information, from the process of intelligent demand generation to the acquisition of basic design data, from the intelligent user’s participatory design to the direct transformation into production information and implementation. In order to realize these changes, intelligent R&D must be supported by eight elements.

1) Establish a unified multidisciplinary collaborative R&D platform.

First of all, the development of intelligent products generally spans multiple professional and technical fields and has a variety of key technical characteristics, involving a high degree of cross-discipline and integration. At the same time, the diversified needs of users also make the product structure and function very complicated, and IT embedded software technology has gradually become the core part of the product, which requires the cooperation of many disciplines such as machinery, electricity and software.

This requires enterprises to establish a top-level architecture that can integrate R&D systems and tools in all different professional disciplines within the enterprise, and form a unified multidisciplinary collaborative R&D platform that can comprehensively manage all professional R&D elements in the product life cycle.

The platform can not only manage the professional drawings, process and material information, but also manage the product function, performance, quality, indicators and their generation process, and integrate programming and management, simulation, optimization, innovation, quality and other tools, so that the R&D system can quickly and efficiently apply these tools, so as to carry out differentiated, high-performance and high-quality product intelligent R&D.. On this basis, knowledge engineering will be used to accumulate knowledge in the process of enterprise R&D, and the ability of serial product development will be formed.

2) Establish a digital prototype to realize simulation-driven innovation.

The core of intelligent R&D is to establish a digital prototype of the product, which is used to support the overall design and structural design, cooperate with the process design, and support the project team to carry out parallel product development.

The main functions of establishing digital prototype include tolerance size analysis, interference check, etc., as well as weight characteristic analysis, motion analysis and ergonomics analysis. In addition, the digital prototype can also provide data information of product assembly analysis, including assembly unit information, assembly level information, etc., to ensure the simulation of product assembly sequence, assembly path, ergonomics, assembly process and working hours. The digital prototype can also be used to evaluate the process, including machining method, machining accuracy, tool path and so on, to realize the CAM simulation of the prototype and the process planning based on the three-dimensional digital prototype.

Digital prototype also plays an important role in the sales stage of products, which can provide vivid dynamic demonstration effect and static product data for product promotion. Through the lightweight technology of three-dimensional model, enterprises can conveniently and flexibly use the original digital prototype model to provide decomposition drawings and schematic diagrams for product training, and can also provide rapid variant and derivative design of similar products to meet the needs of market quotation and rapid organization of bidding and production.

In addition, on the basis of digital prototype, enterprises can also establish virtual prototype for system integration and simulation verification, which can reduce physical tests, reduce research and development costs, shorten research and development cycle and realize simulation-driven design. At the same time, simulation technology can be combined with test management to improve the confidence of simulation results.

In addition, in order to ensure the reliability of products, we must fully consider the engineering elements in the whole life cycle of products, such as process planning, manufacturing, assembly, inspection, sales, use, maintenance and scrapping of products. By using concurrent engineering and DFX technology, the performance, quality, manufacturability, assemblability, testability, product service and price of products in different stages are comprehensively evaluated as early as possible in the design stage, so as to optimize product design and ensure product quality.

3) adopt standardized and modular design methods to improve the product customization ability.

User-centered intelligent research and development will inevitably face the diversity of user needs, which requires enterprises to have flexible product variant design capabilities and form standardized, modular and serialized product development capabilities. As the basic unit of product design, module is the carrier of product knowledge. Modularization and knowledge reuse of products can moderately reduce design risks, improve product reliability and quality, and greatly reduce design cost and design cycle. In addition, it can also shorten product procurement cycle, logistics cycle and manufacturing cycle, and reduce product procurement cost, logistics cost, manufacturing cost and product after-sales service cost. Therefore, it is particularly important to have the ability of product standardization and modular design.

Modular design is to analyze the functions of products with different functions or the same function, different performances and different specifications in a certain range, classify them and design a series of functional modules. Through the selection and combination of modules, different product combinations can be formed to meet the requirements of variant products with different functions and specifications.

Modular design mode can improve design reuse and reduce cost. The combination of R&D management platform and modular design means makes this design mode even more powerful. The implementation of modularization and serialization will produce a large number of product modules and configuration rules, and the amount of data is huge. It needs to be managed by R&D management platform to realize the order and structure of design modules, thus ensuring the accuracy of data and the reusability of knowledge.

4)MBD/MBE design information is highly integrated with production information.

MBD (model-based definition) can define manufacturing information and design information into the three-dimensional digital model of products. MBD not only describes the geometric information of design, but also defines three-dimensional product manufacturing information and non-geometric management information (product structure, dimension and tolerance labeling, BOM, etc.), so that the information exchange between design and manufacturing can maintain an effective connection without completely relying on the integration of information systems. MBD breaks down the barrier of design and manufacturing, and makes the features of design and manufacturing be easily interpreted by computers and engineers, thus effectively solving the problem of integration of design and manufacturing.

After MBD model is regarded as a unified "engineering language", the application of MBE (model-based enterprise) can be further promoted. The data contained in the design model can be effectively transmitted in the process, supply, manufacturing and maintenance services. Through a highly consistent data model, a two-way data flow is formed between PLM, ERP and MES, which makes the manufacturing and subsequent processes highly automated and forms a digital "closed loop" of the whole value chain.

5) Innovative design integrating additive manufacturing and topology optimization technology.

Different from the traditional empirical design mode, the topologically optimized product model is the optimal topological model that meets the performance requirements under given load, working conditions and other constraints. It is a new design method to determine and remove the materials that do not affect the rigid parts through topology optimization, and realize the lightweight of the parts on the basis of meeting the functional and performance requirements. However, topology optimization technology has better effect only when manufacturing process constraints are not considered. Therefore, although engineers have designed a product model with unique structure and high performance through topology optimization, they often give up the advantages of lightweight and high performance because of manufacturability.

With the appearance and mature application of additive manufacturing technology, this big problem can be solved well. Additive manufacturing technology can help enterprises get rid of the limitation of traditional manufacturing technology of reducing materials and equal materials, and design products according to the most ideal structural form, making it possible for products to have "functional priority". Therefore, additive manufacturing makes the value of topology optimization technology fully play, and the integration of them innovates the design and manufacturing process, which is a subversive change for traditional manufacturing industry.

6) Design review of application of virtual reality and augmented reality technology

Virtual reality and augmented reality technology are the bridge between virtual products and real products. By applying virtual reality and augmented reality technology, the design scheme of products and related attribute information of products can be intuitively displayed and experienced in the initial stage of products and before the physical prototype test. Moreover, in the virtual space, it is also convenient for designers to communicate collaboratively, making the whole design review process more convenient and effective, and at the same time, the problems existing in the design process can be more intuitively discovered.

7) Establish wide-area collaborative research and development based on cloud.

In intelligent R&D, based on the Internet, the products and services of enterprises will gradually change from one-way technological innovation, production of products and services to the market, waiting for customer experience, to active contact with users’ service terminals, benign interaction and collaborative development of products, and the subject of technological innovation will turn into users. Its innovation, consciousness and demand run through the production chain, affecting the decision-making of design and production.

Designers will become the organizers of gathering resources among consumers, users and producers, and will play a driving role under the huge network of design and production chain, and will no longer independently undertake all product innovation work. Intelligent R&D will be based on collaborative research and development with suppliers, partners and customers in the cloud, so that everyone can participate in open innovation. Internet-based collaborative design cloud platform can bring together industrial designers and R&D engineers with professional skills from all over the world online to enter the intelligence database, and quickly organize large-scale collaborative operations, which can help manufacturing customers to complete industrial product R&D and design efficiently and conveniently. Once there is an urgent need to be solved, it can be submitted and published at any time on the platform. The platform can help the demanders find high-quality solutions through timely matching and pushing them to the intelligence library with relevant experience, and the whole process is coordinated and controlled.

8) Closed-loop product research and development based on digital twins to drive product innovation.

Product R&D has evolved from focusing on the initial design stage of the product life cycle to focusing on the whole product life cycle. The simulation, testing and experiment in the design stage and the collection and utilization of relevant data in the product operation and service stage have played an important role in product optimization and innovation, which has improved the speed and quality of prototype design.

It depends on the vigorous development of sensing, Internet of Things, big data, AI, simulation, VR/AR/MR/XR and other technologies, which effectively promotes the further landing of digital twin technology, and then inserts strong wings for product R&D and innovation. In the product design and manufacturing life cycle, the sensor can be installed on the physical prototype, and the data collected by the sensor can be transferred to the digital twin model of the product during the prototype test. By simulating and optimizing the digital twin model, the performance of the final product can be improved and enhanced. You can also use hardware-in-the-loop simulation to verify and optimize product performance by using digital twin models for some parts and physical models for some parts. In the stage of product operation and service, based on the establishment of digital twin data and simulation, the areas that need to be further optimized and improved are analyzed, so as to improve the efficiency and quality of new product research and development.

「 2. Exploration and practice of intelligent R&D 」

In order to shorten the product development cycle, enterprises need to deeply apply simulation technology, establish virtual digital prototype, realize multidisciplinary simulation, and reduce physical tests through simulation; It is necessary to implement the idea of standardization, serialization and modularization to support mass customization or product customization; It is necessary to combine simulation technology with test management to improve the confidence of simulation results. In the era of intelligent manufacturing, a number of software companies have emerged in the industry to actively explore intelligent research and development, and they have landed and practiced in manufacturing enterprises.

1) Intelligent R&D tools

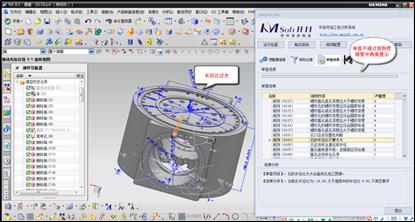

At present, some intelligent software systems have appeared in product research and development tools, which have become the concrete embodiment of intelligent research and development. For example, Geometric DFM PRO software can automatically judge whether the technological features of 3D models can be manufactured, assembled and disassembled. CAD Doctor software can automatically analyze the problems existing in 3D models. Altair’s topology optimization technology can reduce the weight of the structure on the premise of meeting the functions of the product; System simulation technology can analyze and optimize product performance in the conceptual design stage; PLM has been extended forward to demand management and backward to process management. The Teamcenter Manufacturing system of Siemens has structured the process, which can better realize the reuse of typical processes. Kaimu software is also intelligent based on three-dimensional assembly CAPP, machining CAPP and parametric CAPP.

Fig. 1 Manufacturing inspection of parts by Kaimu DFM (source: Wuhan Kaimu Information Technology Co., Ltd.)

2) Individualized demand promotes product modular design.

Modular design can not only improve design reuse and reduce costs, but also greatly shorten the design and manufacturing cycle of products by reuse. Haier’s intelligent interconnection factory in Shenyang has achieved a high degree of flexibility (supporting the production of more than 500 types of refrigerators) and a high degree of automation (the beat can reach 10s/ set). The factory supports the business model of personalized customization of household appliances, and achieves a good return on investment through the premium on a single product. This is mainly due to the R&D team’s successful modular design of refrigerator products, which combined about 300 parts into 23 modules (including 10 standard modules and 13 variable modules), thus greatly reducing the complexity of digital management of parts, semi-finished products and finished products, and simplifying the manufacturing process and supply chain.

3) The concept of digital twins goes deep into product design and operation.

Product research and development has changed from traditional product design and analysis certification to virtual prototype (digital prototype) instead of physical prototype, so as to realize full digitalization of design and processing process. By collecting sensor data, the changes of three-dimensional model and physical model are compared to improve product design. PTC cooperated with Merida, a bicycle factory in Taiwan Province, to build a digital twin IoT concept demonstration product. The bicycle data were collected through sensors, and the riding route and habits were analyzed to give danger warnings. In addition, virtual reality monitoring was carried out according to the serial number of the scanned bicycle. Siemens cited digital twins to describe the consistent data model that runs through all links of product life cycle. With the help of this concept, GE, the American general company, installed sensors on the high-temperature resistant alloy turbine blades of the engine, transmitted real-time data according to the required frequency, received by the software platform, stored in data, and then established a digital model. GE also uses digital twinning technology to manage and update the data of real power stations in real time, capture the operation of real power stations and issue warnings.

4) Virtual reality technology is integrated into R&D.

Virtual reality technology is based on its conception, immersion and real-time interaction, which enables people to interact with the model and produce the same feedback information as in the real world, which greatly improves the efficiency and coordination of design.

Canon’s MRERL system realizes the design process of seamless integration of 3D computer rendering model with real-world objects in real environment, and supports multi-user collaborative work and simultaneous complete product design. It is realized by rendering 3D models of existing components and new design concepts, and combining them. For example, by integrating existing car seats into the projection of new car virtual design, users can see the real environment outside the car and the digital virtual model inside the car, including the newly designed dashboard and steering wheel.

Cave technology is widely used by automobile enterprises and design companies, and virtual reality technology is used to assist product development. Dassault, one of the leading PLM manufacturers in the world, put forward the concept of 3D Experience, and provided solutions in virtual reality (VR) and augmented reality (AR).

5) Simulation-driven innovative design

In the conceptual design stage, simulation technology was introduced to optimize the design, which changed the traditional design process. According to the performance requirements of the product and the change of load during the movement, Altair uses topology optimization technology to calculate the transmission path of output, thus constructing the product skeleton, beautifying the appearance on the basis of the skeleton, and continuously optimizing the subsequent design process in the virtual environment. This pre-simulation design method can not only give full play to the imagination and realize innovative design under the condition of ensuring the performance and reliability of the product, but also realize the lightweight of the product, which greatly reduces the product development cycle and cost. The design concept of Altair is adopted in the front wing of Airbus A380, and the weight of the front wing is reduced by 500kg by using topology optimization technology.

Figure 2 Topological optimization design of A380 leading edge wing

6) Combination of topology optimization and 3D printing

Topology optimization technology helps designers to obtain the optimal structural shape and design lightweight products under the premise of meeting the requirements of given loads and working conditions. However, the product structure after topology optimization is often asymmetric and irregular, which makes it very difficult to manufacture by traditional methods. Additive manufacturing technology, which is typical of 3D printing, breaks this constraint, and any complex product can be manufactured through 3D printing. The perfect combination of topology optimization technology and 3D printing forms a symbiotic technical framework, which greatly releases the potential of design and enables topology optimization technology to give full play to its innovative value.

Figure 3 Symbiosis Technology Architecture

7) The rise of collaborative design mode.

Collaborative design with customers, suppliers and partners based on the Internet to achieve cloud collaboration is also an innovative form of intelligent R&D.. For example, in order to make full use of global development resources and manufacturing resources, Boeing has built a multi-country and multi-organization collaborative design and manufacturing model in different places. Domestic enterprises have gradually begun to try to build innovative product collaborative development teams with foreign R&D institutions through mergers and acquisitions or cooperation, so as to rapidly enhance the company’s product innovation strength.

Generally speaking, it is a complicated and long process to realize intelligent research and development. In addition to establishing a perfect R&D system, enterprises should also realize the automation of data flow in the whole product life cycle through information technology, take users as the center, construct intelligent interconnected products through intelligent R&D, and form a series of product ecological circles, closely link users’ needs, uses and other information with product R&D, and form a closed-loop continuous optimization product R&D and service system.

Quoted from: Intelligent Manufacturing Practice (Author: Huang Pei, Xu Zhiying, Zhang Hefang)